Solvents

Our portfolio is very extensive, as there are 4 mixing systems available, with the help of which we can mix, dispense and deliver any solvent within a short period of time. Thanks to our tank plant, the procurement and storage of raw materials is solved, so we keep an increased stock of all consumable items to meet customer needs as quickly as possible. All our products are manufactured at our Tiszaújváros site!

Wide web flexo printing

We distinguish 2 product categories, thinners and washing liquids. Thinners are required to properly adjust the drying and viscosity of paints and varnishes, while washing fluids are required for continuous cleaning of sheets (polymers), rollers, presses, and parts!

Products:

Thinners- Flexo – Standard solvent

- Flexo N – For high speed printing above 250m / p

- Flexo P – For printing on large machines above 400m / p

- Flexo R – For slower machines below 150m / p

- Flexo E – For fine-pitched high-resolution work at an average speed of 250m / p

- Accelerators – Helps to accelerate the toner, increasing drying performance and speed

- Retarders – Help slow down toner evaporation, reducing drying

- Platewash – For automatic dishwashers for all technologies

- Ultra cleaner – Roller cleaner and press cleaner

- V35 cleaner – Automatic system cleaner for all technologies

Narrow web flexo printing

Here the situation is simpler, we only produce detergents for a narrow track, the development of the products is due to the experience of the last 15 years.

Products:

Detergents- UV cleaner – UV cleaner for general use

- Neuboclean – Adhesive remover and rubber roller cleaning fluid

- Platewash – For automatic dishwashers for all technologies

- Ultra cleaner – Roller cleaner and press cleaner

- V35 cleaner – Automatic system cleaner for all technologies

- Ultra Sonic – Ultrasonic washing liquid

Sheetfed offset printing

Products:

Solvents:- IPA 99,99% – Technical grade Isopropyl

- Reg. IPA – Minimal Water Content of Regenerated Isopropyl

- IPASOL 800 – Mixture of IPA and Ethanol, anhydrous technical quality

- Isofix – Ipa replacement fluid

- Eurostar 65.5 – Tooth certified detergent for conventional paints

- Autowash Rapid – Automatic washing fluid for conventional machines

- UV Mix 6.7 – For hybrid rollers, UV and conventional washing, Fogra certified

- Uniwash 4G – ISEGA and Fogra certified automatic washer for conventional machines

- Elettra UV 1.0 – For hybrid UV cylinders, not suitable for EPDM

- UV cleaner – Manual UV cleaner

- Protegum – Manual roller washer, tire regenerator

- Neboclean – Hand roller washer, rubber regenerator, more aggressive than protegum

- Inkowash – Hand detergent for conventional paints

- DC Flexo WB 1.3 – For water-based paints and varnishes

- DC Flexo SB 2.0 – For UV and solvent washing

Print coatings

The biggest development of our portfolio in recent years. A lot of work and investment preceded us by the time we got to today’s product lines. It is important that all processes are overseen by a strict control standard, as our products are used primarily in food and packaging manufacturing. The market for varnishes is constantly rising due to global demand. In more and more areas, various laminated structures are being replaced with environmentally conscious varnish solutions, helping to make products recyclable, simpler and cheaper.

Foodpack

An important basis of the product family is that it meets all international standards, ISEGA and Nestlé requirements. Ingredients and finished products are also processed separately in our factory! Keeping pace with the continuous growth of packaging production, this product is the widest in our category.

Products:

- Dispersion Isega registered products

- Dispersion direct food varnishes

- Dispersion water and grease resistant varnishes

- Dispersion primers

- Dispersion blister products for packaging

- UV ULM Nestlé varnishes for paper, foil and other raw materials

- UV ULM adhesives for digital printing products

- UV ULM primers for metallized and plastic materials

Pharmapack

Products:

- Dispersion Isega registered products

- Dispersion direct food varnishes

- Dispersion primers

- UV ULM Nestlé varnishes for paper, foil and other raw materials

- UV ULM adhesives for digital printing products

- UV ULM primers for metallized and plastic materials

Printpack

These are our simplest products, the everyday use of classic offset. The biggest challenge in the segment, which mainly uses dispersion varnishes, is competitiveness, so we tried to make products that are easy to handle and competitive in price and quality.

Products:

- Dispersion varnishes

- Dispersion primers

- Dispersion Isega registered products

- Dispersion direct food varnishes

- Dispersion water and grease resistant varnishes

- Dispersion blister products for packaging

- UV standard varnishes for paper, foil and other raw materials

- UV standard effect varnishes for paper, film and other raw materials

- UV ULM Nestlé varnishes for paper, foil and other raw materials

- UV ULM adhesives for digital printing products

- UV ULM primers for metallized and plastic materials

- Oil-based effect varnishes

- Oil-based varnishes

- UV trough effect varnishes

- UV vályú lakkok

Flexipack

Products:

- UV standard varnishes for paper, foil and other raw materials

- UV standard effect varnishes for paper, film and other raw materials

- UV ULM Nestlé varnishes for paper, foil and other raw materials

- UV ULM adhesives for digital printing products

- UV ULM primers for metallized and plastic materials

- Dispersion primers

- Dispersion effects varnishes

Inks

Our company sells printing inks for all areas. Over the years, we have managed to build a portfolio that provides a source of diversified solutions for everyday manufacturing. At our Tiszaújváros site, we not only store, our paint kitchen helps our customers with current color issues. Our suppliers are the world’s leading ink manufacturers in the printing industry, together with our professional background in Hungary and our continuous stock, we try to provide a competitive service for Hungarian printing houses!

Technologies:

Flexo

- UV Flexo

- LED Flexo

- Solvent Flexo

- Wet base corrugated and rolled

Offset

- Conventional

- UV offset

- LED /H-UV offset

Screen

- UV screen

- Solvent screen

- Dispersion screen

Inkjet(digital)

- UV inkjet

- Dispersion inkjet

- Solvent inkjet

Flexo

UV/LED Flexo

Many of the benefits of UV Flexo inks and drying systems have allowed printers to improve print quality, increase productivity and provide a safer printing environment. As a result, the technology has become widespread since the 1980s. Color accuracy and process improvement have helped Flexo printers produce better, faster and cheaper products than ever before. Excellent print quality is achieved with UV Flexo inks, such as finer raster dots and stronger colors, than with solvent- or water-based Flexo inks.Solutions:

- For self-adhesive materials

- For IML films

- Sleeve for printing

- For flexible packaging materials

- For food packaging

- For pharmaceutical packaging

Solvent Flexo

Our team offers a wide range of solvent based paint systems for all packaging. Our product portfolio includes a number of standard paint series as well as a wide range of custom formulations. Each series is optimized for specific applications and can be adapted to meet additional technical and product knowledge to meet your resistance needs.The categorization and brand name of the portfolio, the chemistry of the main binder, and the amount of dyes required during application are taken into account. For solvent inks, we work from concentrates, according to a lot of unique colors and technological needs, printer-specific.

Complex solutions (for printing):

- Front print

- Backside

- Laminating

- Sterilization / pasteurization

Waterbased corrugated board and roll printing

Water-based ink technology increases efficiency and reduces overall printing costs. The strong technology platform for the series used in our portfolio improves print quality and reduces overall packaging costs. We have developed a product line that stands out in a wide range of paper and foil packaging materials.Experience a low-maintenance water-based toner system that improves your printing conditions! The HexaCode, Octacode series is built on the Swiss ordinance raw material platform. This unique product line offers the leading product safety in its category.

Solutions:

- For printing on paper and cardboard

- Developed for food packaging

- Paints based on ingredients, of course

- For highly pigmented series films

- Highly pigmented series paper

- Series developed for printing thermal papers

Offset

Conventional printing

For traditional offset printing, we keep several series on the shelf from suppliers. Depending on the area of use, we can help everyone choose the right product. Although the technology is constantly being pushed back against digital machines, they are still in large quantities on the market, mainly as the packaging manufacturing business grows. Products also include mineral oil-free, plant-based dyes in direct contact with food.Solutions:

- For printing on paper and cardboard

- Developed for food packaging

- Paints based on natural pigments

- For highly pigmented series films

- Highly pigmented series paper

- Trough effect varnishes

UV/LED/H-UV offset

For offset printing, the development of speed, further processing has been accelerated, the first stage of UV dryers was reported, followed by H-UV and is currently the most advanced LED solutions.Thanks to the improvements, the processing and service of the products is immediate, which rivals digital solutions. As a result, the segment will be able to remain competitive in the market for a long time to come. Most of the products here are packaging material, which is constantly growing! Thanks to low-migration solutions, more and more food manufacturers are accepting these dyes for their products.

Solutions:

- For printing on paper and cardboard

- Developed for food packaging

- Paints based on ingredients, of course

- For highly pigmented series films

- Highly pigmented series paper

- Trough effect varnishes

Screen printing

The screen printing method is suitable for decorating a wide variety of flat and shaped surfaces, including various types of plastics, metals, ceramics, glass, etc. Screen technology is mainly used in cosmetics, in tube or glass printing for medicines. The layer thickness of the paints gives the end products an elegant appearance and strong color gloss.

Solutions:

- UV low migration paints for plastic tubes

- UV low migration paints for glass

- Solvent paints for automotive and decorative purposes

Inkjet

For the ever-growing digital market, the supply of consumables is just as important as for the classic analog machines, we were the first in the consumables market to open up to the digital market in the supply of consumables. Machine builders can only avoid paint manufacturers’ direct contact with printers for hours, a process that is also important to users because their digital machines are more competitive in the market and generate more revenue.

Solutions:

- For printing on paper and cardboard

- Developed for food packaging

- Paints based on ingredients, of course

- For highly pigmented series films

- Highly pigmented series paper

Finishing foils

Hot stamping

Solutions:

- For self-adhesives

- For cartons

- For plastics

- Tubes

- For packaging materials

- For UV varnishes, digital varnishes

- Textile

- For T-shirt printing

- Leather base material

- For digital varnishes and toners

- Security solutions

Cold foiling

Solutions:

- For self-adhesives

- For cartons

- For plastics

- Tubes

- For packaging materials

- IML films

- Sleevek

- For digital toners

- Security solutions

Thermo lamination

Solutions:

- For self-adhesives

- For cartons

- For plastics

- For digital prints

Cold lamination

Solutions:

- For self-adhesives

- For cartons

- For plastics

- For digital prints

Self-adhesive lamination foils

Solutions:

- For self-adhesives

- For plastics

- For digital prints

- For flexible packaging materials

Pressroom materials

Offset products

- Water additives

- Machine room chemicals

- Anilox rollers

- UV lamps, IR lamps, reflectors

- Rubber blankets

- Varnishing cloths

- Powders

Water additives

Due to the constant change in technology, machines that are running faster and faster, and non-alcoholic printing, printing inks, printing plates, and printing types need to be well coordinated.

Given the wide range of printing materials, colors, wetting unit types, and other printing conditions, differentiating water additives is essential to a trouble-free printing process. The machine, toner, water, paper, temperature, and legal regulations greatly affect the printing process, including the wetting solution concentrate.

The CNI team offers an ideal damping solution for all machine types and its water softening system that meets quality standards – while minimizing paper waste.

Using our Fount solutions, ensure a constant pH of the damping circuit if the following typographic advantages occur:

- There is no negative color build-up in the non-printable areas of the rubber sheet

- Remove rust from plates, covers and pressure rollers

- No point increase

- Optimal free running of discs

Chemicals

Sometimes only a small step is missing for the perfect printing result, and this is very often achieved with our perfectly coordinated printing tools. The products not only give your prints a perfect look, but can also increase productivity e.g. reduces downtime.- Color remover

- Special cleaning agents

- Liquids or sprays

- Ductfoil

- Press cleaners

- Rubber coatings

- Pastes for protection and deep cleaning

Anilox rollers

Types:

- Chrome cylinders

- Ceramic rollers

- Sleeve rollers

- Varnishing rollers

UV lamps, IR lamps, reflectors

Ultraviolet drying (commonly known as UV drying), used in the printing industry, is a photochemical process in which high-intensity ultraviolet light is used to instantly cure or dry inks.

The UV curing process is based on a photochemical reaction using light instead of heat. Liquid monomers and oligomers are mixed with a few photoinitiators and then exposed to UV energy. As a result, the ink dries and dries immediately.

UV-curable paints have been created as an alternative to solvent-based products. Conventional heat and air drying is accomplished by evaporating solvents, which reduces the original application by more than 50% and creates pollutants.

In contrast, during UV curing, there is no solvent that evaporates, no environmental contaminants are formed, and the paint layer does not lose its thickness and volume. As a result, productivity, waste, energy consumption and pollution are reduced in less time.

We supply a number of components for UV systems:

- 4.0 Lamp and Alt-Gator switch

- Ultraviolet lamps

- Microwave lamps

- Metal halide UV lamps

- UV lamp system reflectors

- Measurement, monitoring and control of UV lamps

- UV lamp accessories

- Infrared lamps

- UV integration products

- UV LED lights

- Mercury leaks

- Ceramic and metal ends

- Electronic power supplies

- Chokes, igniters, capacitors

- Mini UV laboratory unit dryer

- Low pressure and amalgam UV lamps

Rubber blankets

The stable and high-quality printing process depends on many parameters. One of the deciding factors is choosing the right rubber band. CNI offers a wide range of offset rubber sheets that are specifically tailored to your application.Our customers enjoy a number of benefits when using our offset sheets:

- High-resolution, sharp point reproduction.

- Minimal point increase

- Excellent large format printing.

- Resistant to mechanical and chemical effects.

- Format border insensitivity.

- Very good paper release (“Quick Release” effect)

- High resistance to creasing (fracture resistance)

- Long service life

Varnishing blankets

- Dispersion wipes

- UV varnishing cloths

- Cutable hybrid cloths

- PU recyclable wipes

- Compression underlays

Powders

Our Anti Set-Off powders are characterized by a uniform particle size and an even distance placed on the substrate. These properties ensure that the sheets are not laid or folded in the transport stack – so lamination, lamination or varnishing of the sheets is not an obstacle.

CNI Anti Set-Off powders are economical to use, have perfect flow characteristics and ensure even distribution on the substrate due to their good particle sorting properties. In addition, the paint absorbs them perfectly, so they inhibit lump formation.

Special manufacturing processes give our powder hydrophobic, water-repellent properties, which makes them particularly suitable for finishing dispersion-coated prints.

Flexo

Anilox rollers

Types:

- Krómhengerek

- Kerámiahengerek

- Sleeve hengerek

- Lakkozó hengerekChrome cylinders

Sleeve rollers

Our products provide greater productivity and flexibility by using pre-assembled molds for quick change. These are very effective for short jobs, re-pressures and design changes, as sleeves can be removed after printing and stored with the pressure plates. The core of the rollers is made of foamed PU, which provides a light and strong foundation for secure printing dreads.

Features

- Exceptional quality and value

- Flexible production time

- Very large dimensional tolerance, TIR

- Hardness 80-90 ° ShoreD

- Lightweight, thick sleeves and adapters

- Conductivity over the entire sleeve surface

- High quality materials – Vulcolan®

- Base confirmed by flight certificate

- Wind protection – low vulnerability

- Steel protective ring and aluminum ends

- Stainless steel cuts

- Optional RFID chips

- Custom detailing is possible

Printing cylinders

Our company, in close cooperation with printing press manufacturers, often supplies the standard equipment for new machines. The production of precision CNC machines ensures a concentricity of ± 0.005 mm. Gears (hardened and polished), shapes and spacers and register rings – made in Germany, of course – are key factors in print quality.Options:

- Hard anodized layer

- Hardened and ground gears

- Extra light design

Advantages:

- Optional hard anodized layer for increased wear protection

- Optimized weight with pipe material with inserted surfaces

- Optionally hardened and ground gears

- Short delivery time

Magnetic cylinders

Thanks to full supervision of all production steps, CNI ensures that strict quality standards are met. The results are magnetic cylinders with the highest possible dimensional accuracy.

Optionally integrated techniques for vacuum and compressed air, as well as holes for flexible tools, offer many options that go beyond standard daily applications.

Modern machines allow the production of cylinders up to 750 mm in diameter and 3,000 mm long.

Advantages:

- Fine pole height for perfect adhesion

- Positioning line and / or scaling to adjust flexible tools

- Extremely strong adhesive for special applications using neodymium magnets

- Dynamic and static fine balance

- Hardened centering can be improved for perfect concentration

- We offer detailed inspection and evaluation of magnetic cylinders:

- Magnetic cylinder inspection

- Positioning system with drill and dowel pin

- Short delivery time

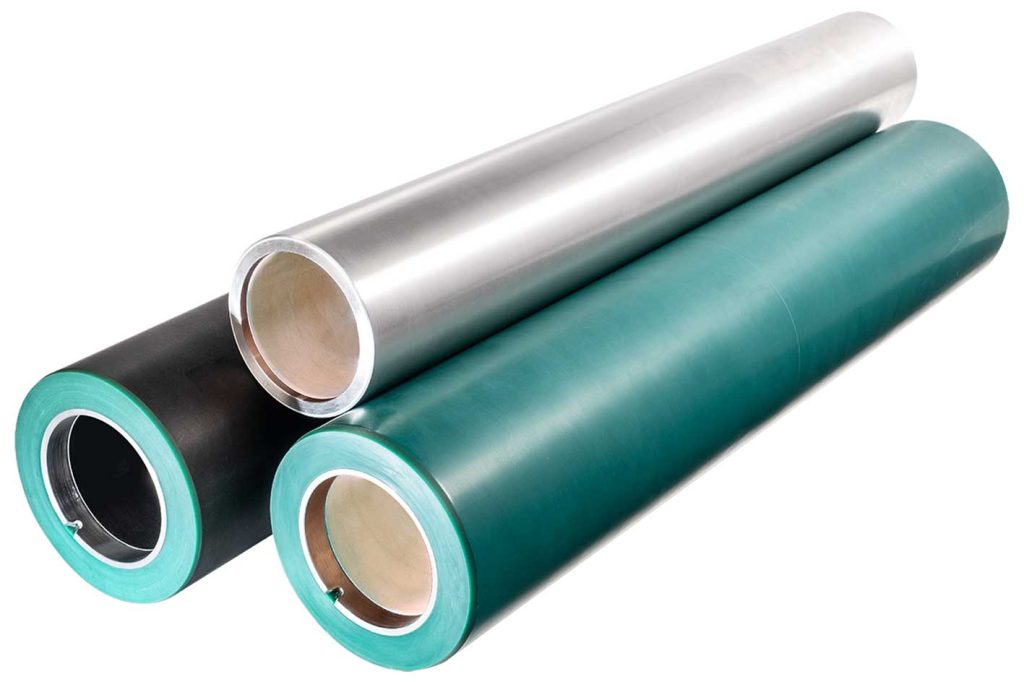

Rubber sleeves

Rubber sleeves have been used successfully for years for label printing and have proven value in proven printing processes.

Sleeves with special rubber coating are used when full surface painting, coating and lamination is required for the label and film material. Standard sleeves are available in stock for the following speed sizes, Z88 and Z96 1/8 ”cp. The sleeves can be placed on the support cylinder in any width. The “AirBoy” assembly instructions and the required air cylinders are provided by CNI from a single source.

Advantages:

- Easy to record and place

- Variable working width

- Standard sizes are always available

- Comprehensive discussion on machine conversion to legume technology

- All parts are delivered from one source

- Short delivery time

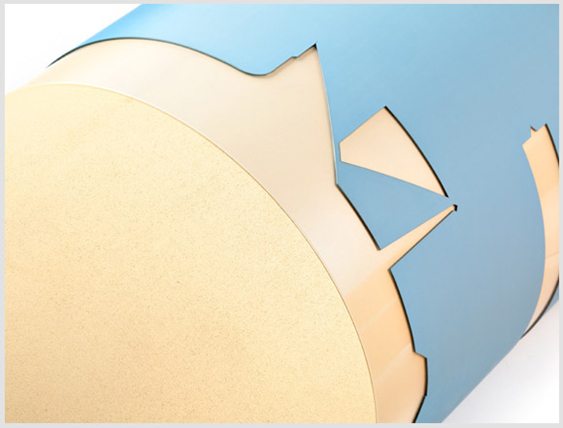

Flexible dies

Our sheets provide maximum performance in tool cutting with full consistent results – whether paper, film or composite. From the experience of our customers, our strong cooperation with leading material suppliers and more than 50 years of experience, Spilker has been able to develop punch plates that still meet tomorrow’s quality standards.

Features:

- Available in thicknesses from 0.3 mm to 1.0 mm (optional up to 1.5 mm on request)

- Cutting angle between 50° and 120°

- Surface refining with nickel coating

- Microperforation solutions

- Optional laser training

- Different cutting heights in a flexible tool

- Optional non-stick coating (food safety and FDA approved)

- Dimensions up to 800 x 1080 mm in one piece

- Qualified

Your benefits:

- High flexibility through high-quality flexible tools for universal use in paper and film production

- Maximum cutting quality is possible with the improved cutting geometry “Gap above perf”

- High durability due to surface refinement

- Easy and fast online ordering with the Spilker Toolbar

- Short delivery time

Doctor blades

Blades are an essential part of flexo and gravure printing, each machine has its own individual expectations, depending on the design of the chamber and the type of product being made on the printing press. All profiles can be found in our portfolios.Types:

- Metal

- Plastic

- Specially coated blades

- Crack seal

- Knife cutting equipment

UV lamps, IR lamps, reflectors

Ultraviolet drying (commonly known as UV drying), used in the printing industry, is a photochemical process in which high-intensity ultraviolet light is used to instantly cure or dry inks.

The UV curing process is based on a photochemical reaction using light instead of heat. Liquid monomers and oligomers are mixed with a few photoinitiators and then exposed to UV energy. As a result, the ink dries and dries immediately.

UV-curable paints have been created as an alternative to solvent-based products. Conventional heat and air drying is accomplished by evaporating solvents, which reduces the original application by more than 50% and creates pollutants.

In contrast, during UV curing, there is no solvent that evaporates, no environmental contaminants are formed, and the paint layer does not lose its thickness and volume. As a result, productivity, waste, energy consumption and pollution are reduced in less time.

We supply a number of components for UV systems:

- 4.0 Lamp and Alt-Gator switch

- Ultraviolet lamps

- Microwave lamps

- Metal halide UV lamps

- UV lamp system reflectors

- Measurement, monitoring and control of UV lamps

- UV lamp accessories

- Infrared lamps

- UV integration products

- UV LED lights

- Mercury leaks

- Ceramic and metal ends

- Electronic power supplies

- Chokes, igniters, capacitors

- Mini UV laboratory unit dryer

- Low pressure and amalgam UV lamps

Photopolymers

We offer environmentally friendly, solvent-free solutions for many Flexo and high pressure applications. Water-washed photopolymer sheets. Water wash, photopolymer sheets give even results in all cases, providing finer resolution and excellent ink transfer.

Aquaflex Optima:

Specifically used for flexo paints, including UV, alcohol / ester and other solvents.

Rapidoflex:

Rapidoflex is a high quality UV flexo sheet that can be used to print narrow track labels. High quality and as fast as possible, ready to print in 20 minutes without the use of solvent.

Aquaflex Aqua:

Developed for printing high quality, water-based inks.

High pressure, Letterpress:

Torelief DHX4 analog and digital plates can be used for all high-pressure, semi-rotary and dry offset applications.

Foam tapes

Flexo

SCAPA® adhesive adhesives are specifically designed for high-speed flexo printing. Scapa Exafit® double-sided, compressible foam adhesives meet the most stringent needs of the flexo industry. The products are characterized by unparalleled attention to detail and outstanding quality. There are many different types of adhesion and thickness available. For every stage of cliché use, from testing to edge sealing, Scapa offers the right product for your application.Available types:

- Softer, rigid double-sided adhesive for halftone printing at high machine speeds. Normal / strong adhesion on the side of the cliché and easy to remove.

- Semi-rigid double-sided adhesive for excellent halftone and combined printing at increased machine speeds. Normal / strong adhesion on the side of the cliché and easy to remove.

- Hard double-sided adhesive for premium tone and raster printing. Normal / strong adhesion on the side of the cliché and easy to remove.

High pressure

ORAFOL® Oraflex double-sided adhesives offer a complex portfolio for photopolymer or varnish for flexo, letterpress and label printing. The adhesives are designed to be removed from both Sleeve and metal rollers clearly and without residue after use. Comfortable to use with both Sleeve and Cylinder. Easy and clean removal from the pressure plate, resistant to chemicals and solvents and does not damage the plate. Improved print quality through good bonding between plate and adhesive.

Available in 0.1 mm, 0.2 mm and 0.3 mm thicknesses.

Laminating adhesives

Most of the flexible packaging is all laminated, it is important to know all the elements of the project in order to choose the right product, as the content, structure and printing of the packaging all influence which adhesive we need to laminate the given products.Available products:

Solvent-free

- Does not contain solvent

- Energy cost savings during application, “sustainability”

- Low cost of use

- High speed lamination

- Non-flammable material

- Low equipment investment

Solvent

- Wide range of systems for non-standard use

- High initial bond strength

- High dry matter content during application (> 50%)

- Damage to oxygen and water vapor

- High lamination speed (> 300 m / min)

- Wide range of covered structures

Dispersion adhesives

- Use a standard laminator

- Immediate compliance with food regulations

- No solvent release

- Higher initial shear strength, allowing for immediate splitting

- Easy to run and operate

- Long service life

Chemicals

Sometimes only a small step is missing for the perfect printing result, and this is very often achieved with our perfectly coordinated printing tools. The products not only give your prints a perfect look, but can also increase productivity e.g. reduces downtime.- Color remover

- Special cleaning agents

- Liquids or sprays

- Press cleaners

- Pastes for protection and deep cleaning

Printing machines, parts

UV/LED drying systems

Printing areas:

- Narrow track

- Wide track

- Sheetfed printing

- Metal Deco

- Digital

- R&D activity, Laboratory machines

ArcLED:

ArcLED is a hybrid UV system that allows the press to use any combination of mercury arc (UV) and LED technology perfectly through the same cartridge.

E2C:

The GEW E2C is the most powerful low-energy UV drying system for narrow-track printing. With the RHINO electronic power supply, E2C increases the drying of paints and varnishes, which increases machine productivity and makes printing more secure.

E2C-RHINO systems use significantly less energy. They enable the color printing process at full production speeds of as little as 90 W / cm (230 W / inch).

Infrared cassette:

Water-based paints and varnishes are widely used in the label printing market, requiring a hot air dryer to evaporate the water content, leaving the remaining pigment on the surface. The increasing use of UV inks and varnishes means that printing machines may need to dry for both UV and water based coatings. On some machines, this means that both water-based and UV processes are not possible. To address this, GEW has developed a cassette infrared system for water-based inks that simply slides into the luminaire instead of the UV cassette and operates with the same control technology.

NUVA2:

NUVA2 is the most efficient UV technology for color UV Inkjet printing and high-speed coding, marking and serial numbering. The NUVA2 is a fully air-cooled UV drying system. Available up to 250 cm wide.

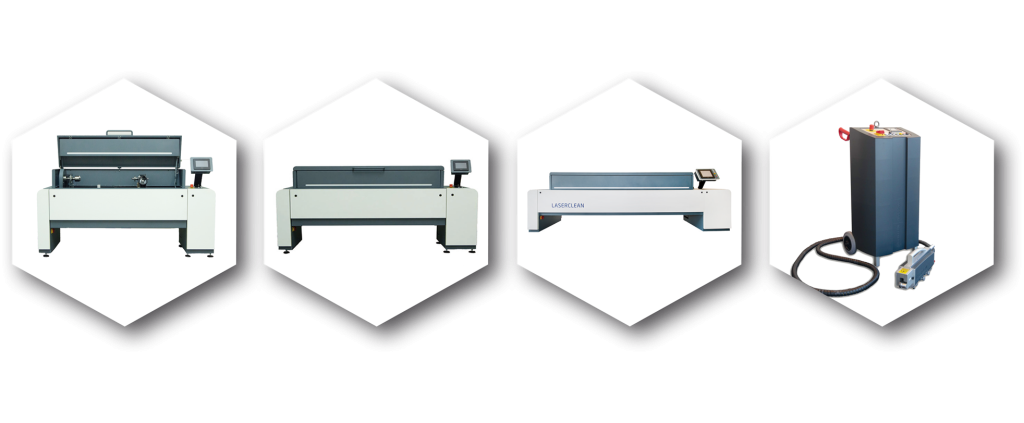

Platemaking

For use with Aquaflex and Rapidoflex sheets:

Our AQF processing range ensures that our plates enjoy the fastest washing time in the world, with high quality results developed to fully comply with the latest environmental legislation.

For letterpress and flexo printing:

Our Aquaflex lighting units are designed and built for use with Torelief, Rapidoflex and Aquaflex panels. They are available in two sizes and allow sheet metal production of up to 900 mm x 1200 mm.

Laser anilox cleaning

Technical specifications and application

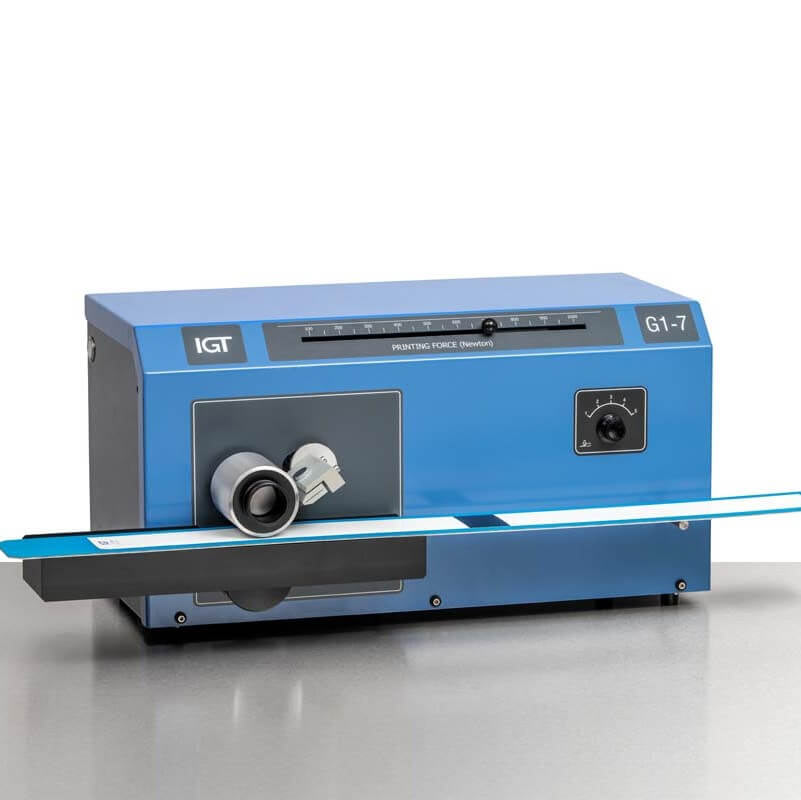

The ALCS 1000 S (F) is marketed primarily for its reliable, fast and flexible use of quality. Our new machine is designed for narrow-track companies that want to do in-house laser cleaning. ALCS 1000 S (F) reduces the use of chemicals and paints as frequent cleaning is simpler and more economical. At the same time, print quality always remains at the highest level as the rollers and sleeves work in a novel way. The purchase of the ALCS 1000 S (F) is an investment in high quality printing and efficient cleaning of anilox rollers. The improvement of the surface tension and the improvement of the paint application are outstanding!Laboratory and paint kitchen tools

Our solutions

- Offset

- Flexo

- Gravure printing

- Screen

- Dryers (UV / LED and IR)

- Abrasion resistance

- Drying test